Wherever you are and whatever your application in ceramics or polishing, Baikowski® develops fully customized oxide solutions that are tailored to your specifications and process requirements. We deliver user-friendly, ready-to-use materials—engineered for seamless integration and consistent performance, so you can focus on achieving optimal results.

What is Baikowski® added value for custom oxide materials?

At Baikowski®, we specialize in tailor-made high-purity oxides for demanding industries such as aerospace, electronics, optics, energy, and medical devices. Every customer has unique requirements, which is why we customize our solutions based on:

- Chemical composition & purity (stoichiometry, dopants)

- Physical properties (specific surface area, particle size distribution, flowability, sinterability)

- Final form (powder, slurry, spray-dried granules)

This customer-focused approach ensures consistent quality and perfect compatibility with your industrial process.

👉 Visit our Ready-to-Use & Ready-to-Press Oxides page to explore our alumina, spinel, and zirconia solutions designed for high-performance applications.

How does Baikowski® customize fine mineral products?

Customization begins with a deep understanding of your application. Whether you’re working on ceramic matrix composites, transparent ceramics, or precision polishing, we adapt our materials through:

- R&D collaboration from first contact to full production

- On-site testing and feedback loops

- In-house pilot unit capable of producing 1 kg to several tons.

Who can you contact for product development ?

Our dedicated R&D team is composed of scientists and engineers with strong expertise in ceramic materials, formulation chemistry, and process engineering. We work closely with our customers and also maintain long-term partnerships with top international research institutions to stay at the forefront of innovation.

👉 Conatact-us for your custom needs

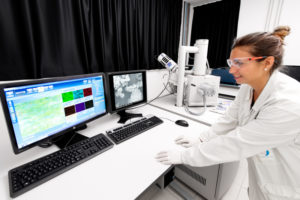

What kind of advanced equipment does Baikowski® use for innovation?

We rely on state-of-the-art analytical tools to ensure the highest material quality and support breakthrough developments. We use anlytical tools such as:

- High resolution ICP-AES and XRF (X-Ray Fluorescence) to quantify the minor & major elements respectively

- XRD (X-Ray Diffraction), SEM-EDS & optical microscopy for microstructure and phase analysis

- Laser diffraction particle size analyzers

- Rheometers, DSC-TGA for thermal and rheological behavior

👉🎥 Watch our video on thermogravimetric and DSC analyses to explore how we characterize product behavior and formulation precision.

Can Baikowski® handle industrial-scale customization?

Yes! Our pilot unit bridges the gap between laboratory innovation and full-scale production. Designed for agile scale-up, it allows rapid delivery of custom materials—from 1 kg to several tons—with the same high standards applied to all batch sizes.

What types of projects can Baikowski® support?

We provide custom materials for a wide range of technical applications, including:

We provide custom materials for a wide range of technical applications, including:

- High-purity alumina for ceramics, polishing, and electronics

- Spinel and zirconia for transparent and structural components

- Phosphors for lighting, imaging, and detection

- Nanodispersions for optical coating, dental restorations and more

Are you looking for an expertise to help you achieve better performance in your technical product? Are you developing a new technology based on fine oxides? We’re here to help you achieve superior performance and long-term reliability.

Where can I learn more about Baikowski’s oxide innovations and product offerings?

👉You can browse and download our latest technical white papers to explore real-world use cases, R&D insights, and advanced oxide formulations for technical ceramics, polishing, and more. Looking for a specific material? Use our product browser to filter by application or chemistry