Frequently Asked Questions about CMCs

🔬 Ceramic Matrix Composites (CMCs) for High-End and Sustainable Applications

CMCs are advanced structural materials that delvier superior performance for many high-end applications, like in aerospace engines, automotive components, heat shields, energy systems, and industrial insulation. Baikowski superior Ox/Ox CMCs solutions offer excellent thermal and chemical stability with good mechanical properties, particularly in oxidizing environments.

✅What is a CMC material?

A Ceramic Matrix Composite (CMC) is a ceramic matrix coupled with embedded ceramic fibers. This unique association of materials revolutionized the aerospace industry, making parts more resistant to extreme conditions and lighter compared to the previous technologies. CMC materials prevail over most of the drawbacks of conventional technical ceramics, which are low fracture toughness, limited thermal shock resistance & brittle failure.

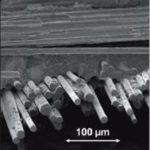

Fibers are just a fraction of the thickness of a hair (see the picture enclosed), and yet they can prevent an airplane part from breaking in extreme conditions. Baikowski® develops special submicronic high purity alumina and mullite solutions for performing ceramic matrix in oxide-oxide CMCs, such as BA15-PSS, SM8 and SLAz, a high-purity fine alumina doped with nanozirconia.

Our engineered solutions ensure excellent infiltration, controlled porosity, fine microstructure, and reliable performance in extreme environments.

✅What are the Properties of the ceramic matrix composites?

CMC technology was developed to face extreme conditions, thanks to its remarkable properties:

- Thermal resistance: while technical ceramics are proven thermal insulators, CMC is adding dimensional components (namely fibers, matrix and pores) that enhance the resistance to thermal shocks.

- Lightweight: compared with the previous composite technologies used in extreme environment, a CMC part is much lighter. For example, it is 1/3 the weight of nickel superalloys for a similar part.

These two characteristics are part of the reduction of fuel consumption and pollutant emission, inasmuch as engines can run hotter, combusting fuel more completely.

- Fracture toughness: CMC material is less brittle than a conventional technical ceramic, since fibers contribute to bridge the cracks

- Electrical insulation: oxide CMCs show dielectric transparency, unlike other types of CMCs.

- Chemical stability: High Purity Alumina matrix shows excellent corrosion resistance against most chemicals

Those properties are strengthened by Baikowski’s control of particle size & size distribution in the delivered products (d50<0.2µm). Moreover, we deliver a wide product range (powder & slurry), with high chemical purity, 100% α alumina. Our slurries are provided with high solid content.

✅What are the main applications?

They are used in various sectors ranging from automotive components and aerospace structures to electrical insulators and biomedical devices.

- Components for gas turbines (turbine blades, combustion chambers)

- Heat shield systems for aerospace

- Various burners

- High performance braking systems

✅What are the main benefits of Baikowski® Ox/Ox CMC solutions?

View Ox/Ox CMC related products

Ceramic matrix requires precursors much smaller than 10µm for:

- Easy processability (intimate mixing during CMC fabrication), including spray-dried forms

- Low sintering temperature

- Good mechanical properties after sintering

We provide powders and slurries especially designed for oxide CMC application. Looking for further partnership? We develop customized solutions:

- Powder suspensions

- Material composition

- Repairable CMC

✅Learn more in our white paper:

ADVANCED MATERIAL FOR OXIDE CMCs

White Paper

4N Alumina & Mullite solutions

Discover all our White Papers