|

Sections 1. Resources consumption |

Targeting sustainable industrial activities goes further than taking simple “green” and often short-term actions to reduce a carbon footprint.

At Baikowski, it goes from common industrial good practices to real efforts for a positive impact in the long run, whether it is from an environmental or local perspective

1. Resources consumption

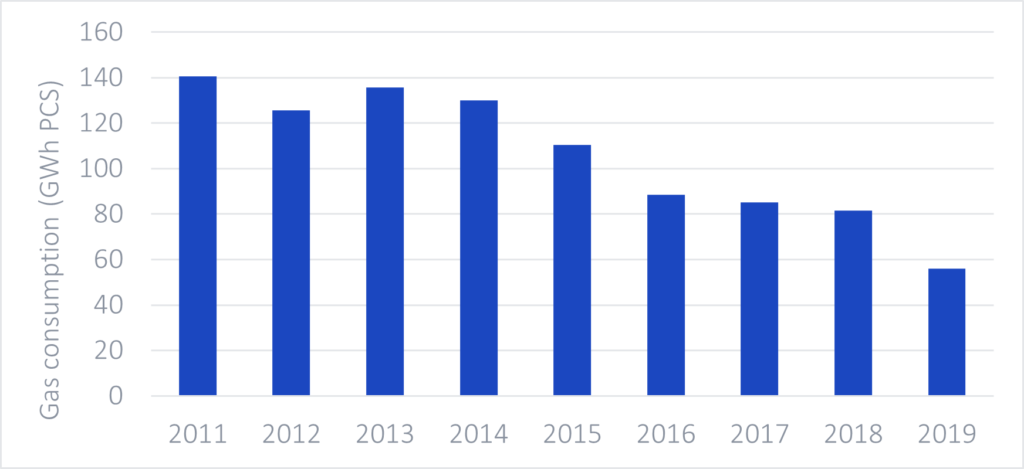

Reducing gas consumption at Baikowski France

To bring our products to high temperatures and thus turn them into high-end materials, Baikowski uses kilns working with natural gas. Being aware that our activities require an important use of this resource, we are closely monitoring our consumption and taking action to reduce it gradually. Indeed, we can see a progressive decrease in our consumption during the past decade:

Sure, these figures must be read knowing the volumes produced each year. We are moving towards always more demanding markets with higher and higher value-added products. This strategy led us to the production of other types of fine oxides aside from aluminum oxide. Manufacturing these higher value-added products turns out to be less energy-consuming than alumina production and comes together with a decrease of production volumes of more standard alumina.

In addition to this trend, we focus our efforts on optimizing our facilities continuously. That is why we invested in a new technology of burners for our furnace a few years ago. These are heat self-recovery burners, enabling to reduce smoke spillage while reinjecting captured energy back into the system. The result was undeniable: we cut back on our gas consumption by 25% regarding the kilns concerned! Moreover, we struggle against the heat loss and to the extent possible, we fine-tune our facilities to make them as heat tight as possible.

In 2022, following the call for application “Expedite the industrial transition” launched by The French Agency for Ecological Transition, ADEME, Baikowski® has been taking part in the experiment consisting in the opportunity study of the low-carbon energy mix of its Poisy production site. In 2024, Baikowski®’s ABC (Alumine Bas Carbone/ Low Carbon Alumina) project has also been selected as a winner of the France 2030 call for projects!

Water Management Efficiency: A Long-Term Commitment at Baikowski® Group

At Baikowski®, reducing water consumption has been a priority for over two decades. As part of our ongoing commitment to sustainability, we have continuously implemented innovative solutions to optimize water usage, reduce reliance on municipal supplies, and minimize our environmental footprint.

Baikowski Malakoff Inc. (BMI)

Baikowski Malakoff Inc. (BMI)

As early as 2003, Baikowski’s subsidiary in the USA recognized the importance of water conservation and made it a key focus of its continuous improvement strategy. Following an in-depth process assessment, the company initiated a process water re-use system in 2007.

By 2020, this initiative had already resulted in a more than 60% reduction in water usage per unit of production.

Baikowski® France

At our Poisy site, we have further reinforced our commitment by investing in new technologies to optimize water consumption. As a result, in 2024, we achieved a durable 20% reduction in water use per tonne of product, contributing to both environmental preservation and energy efficiency.

Discover our environment and energy policy

2. Waste treatment/recovery at Baikowski France

Baikowski captures and retreats its gas emissions and effluents through two separate mechanisms that are feeding each other; the STEL and the Sox. These two tailor-made facilities are not only a mean to reprocess our gas & liquid effluents to neutralize them, but also to recycle them with by-products : sodium bisulfite and calcium sulfate. Processing gaseous and liquid effluents is just a good practice of industrial manufacturing. Nevertheless, creating by-products is a real asset for Baikowski France!

– BINA (Sodium Bisulfite)

The Sox mechanism enables us to process the gas produced while manufacturing high purity alumina. We obtain a by-product that is currently sold for water treatment or as a bleaching agent: the bisulfite. Since March 2023, we can also adress the agri-food market thanks to the ISO 22000 certification and in particular the sugar market.

– Sulcabai (Calcium Sulfate)

We have been developing a custom-made facility to process liquid effluents coming from our manufacturing process. It gives the ability to neutralize the effluents and it goes even further; we create an upgraded by-product: the calcium sulfate! Our Sulcabaï (in French, sulfate de calcium Baikowski) is used in agriculture for fertilization and aeration of the soil. It brings many benefits; for instance, it helps for desalination and takes away soda from saline soils. We produce about 1,2 tons of Sulcabaï for 1 ton of alumina being produced.

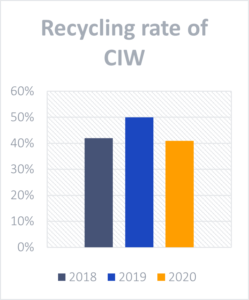

Common industrial waste (CIW) and other waste

We make sure that we separate and recycle waste as much as we can. Indeed, between 40% and 50% of non-hazardous industrial waste are recovered at Baikowski. For example, our IT equipment at the end of life is collected by the company AFB two times per year. This company refurbishes our equipment to give it a second life, while employing in the long term people with disabilities.

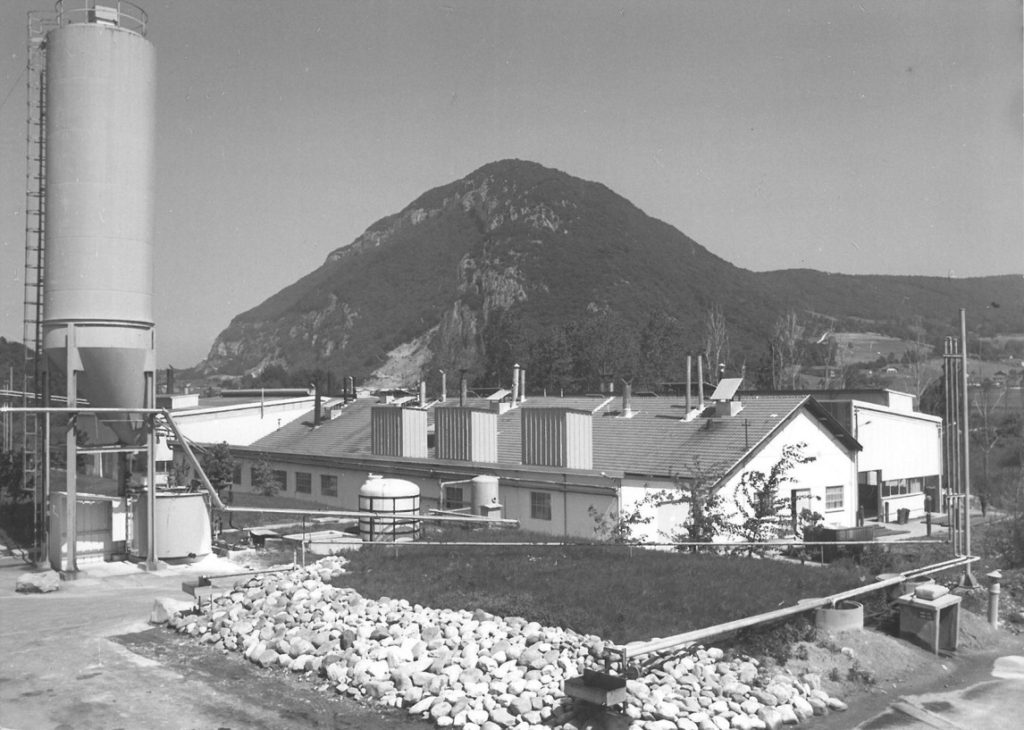

3. A company deeply rooted in its local environment

Founded in 1904, Baikowski® is a well-know company in Annecy area. Indeed, Baikowski arrived in Annecy in 1919 due to its proximity to the hydroelectric equipment essential to its development and due to watchmaking industry (Swiss & Savoyard) booming at that time. The company thus drove up local employment and benefited from an enabling environment for a sustainable growth. During WWII, although the plant was partly destroyed, the employees continued to produce the precious crystals. In 1954, the plant in Poisy was created – it is still existing today and employing about 130 people locally.

Hence, the strong local anchoring of Baikowski France highlights our long-term approach: to continue to be part of the local life in a virtuous, respectful way.

Constantly willing to reduce noise emissions

We managed several projects simultaneously to reduce our noise emissions and thus decrease the disturbance for our employees and the residents

- We had a tailor-made silencer system manufactured in France for the fan of our gaseous effluent treatment plant. The setup was made by a local company. Once the equipment was settled, we measured an ambient noise lower by -3dB. This represents a level of noise for the residents divided by two! In an ambient noise reduction approach, we have also installed a variator on the evaporative cooling towers of the same facility.

- In our plant, we put a cowling on the vacuum pumps. It was also made by a local French company. The sound attenuation has been more than efficient; while a difference of -3dB means a level of noise divided by two (exponential curve), here we measured a drop of -30dB in the plant!

These actions have a positive impact for all; residents enjoy more calmness, while employees see their working conditions improved.

Long-term projects within Annecy conurbation

In the spirit of long-term, inclusive development with its environment, Baikowski is working with local authorities on various subjects:

- A heat recovery system is being explored, which goal is to re-inject the heat losses of the facilities into the municipal network. It would be profitable for the residents who could enjoy a local source for their heating network!

- We engaged a project of solar panels installations, as part of the governmental plan “climate, air, energy 2050”. This project is also being studied.

- We actively participate in the local mobility plan for companies, with soft mobility being established since 2017. Thus, Baikowski is involved in 2 to 3 meetings per year with Annecy conurbation, and benefits from a regulatory support. Internally, we are promoting soft mobility. For instance, we participated in an e-bikes purchasing campaign dedicated to employees who could enjoy competitive pricing.

Hence, Baikowski chose to remain deeply rooted to its local environment, through durable and positive actions for the residents and all its employees. The sustainability of the company also goes by a smart management of resources needed for a proper running of the production units, and treatment & recovery of waste & emissions related to its industrial activities. Thanks to all those long-term actions, Baikowski has been a long-lasting company, since 1904 and for a long time to come!

4. Sustainable applications and markets

We want our products to serve markets that are nurturing a brighter future, with high value added. More and more applications that were exclusively dedicated to metal or polymers are moving toward the use of fine oxides, more resistant and long-lasting on many points.

Indeed, there is no longer any doubt about the numerous benefits in using technical ceramics:

- Enhanced mechanical resistance, thanks to the intrinsic strength of ceramics

- Stable even at very high temperatures

- Lighter than some metals

- Chemically inert (no corrosion, neither oxidation)

- Remarkable optical properties, in diffusion for non-opaque ceramics in general and in transmission for transparent ceramics.

All these properties are making the technical ceramic a major ally in the pursuit of performance, while remaining a non-toxic, durable material. Let us explore some examples of farsighted applications in which our products play a role.

Ceramic Matrix Composite – CMC

This material revolutionized the aerospace industry. Indeed, in consists of a ceramic matrix associated with integrated ceramic fibers. These fibers, finer than a hair, yet can prevent a plane part from breaking brutally.

The CMCs brought a better resistance to extreme conditions (temperature and mechanical constraints) compared with the previous technologies. Therefore, the jet engines can run at much higher temperatures and consume the fuel more completely. Moreover, the CMCs enabled to significantly lighten the components, due to their intrinsic composition. That is why the CMC technology contributes to reduce both the fuel consumption and the greenhouse gas emissions of air traffic.

At Baikowski, we play a part in the technical evolution of the ceramic matric composites through our innovative products. Indeed, we design raw material that can be sintered at relatively low temperature while keeping excellent mechanical properties after sintering. This kind of evolution, once again, enables to lower the energy consumption in our customers’ process, as much as the associated costs.

Learn more in our Ox/Ox CMC White paper

High-power LED

The light-emitting diode (LED) is more and more popular and have been supplanting the conventional lighting just for a few years. Its effectiveness is widely recognized for its brightness and energy efficiency. The common LED has a very low energy consumption and do almost not heat up. The LED is also long-lasting compared to most of other lighting technologies, thanks to its outstanding mechanical properties.

The high-power LED emerged more recently, especially in the automotive market. In 2020, most high-end cars were equipped with main-beam LED headlamps. Nowadays, high-power LEDs are more effective than the previous automotive lighting technologies.

High-power LED need a ceramic convertor to process the native blue light into a more eye-friendly light, and thus reach an optimal functioning. Indeed, unlike polymer matrix, ceramic convertors enable the system to run at higher temperatures and offer an optimal diffusion of light.

Learn more about light conversion

Baikowski offers tailor-made developments in the field of ceramic convertors, aimed at answering to the technological challenges of the future. Our YAGs and LuAGs are well-known for their high sintering reactivity and the homogenous distribution of activators within the lattice and thus targeting maximal quantum efficiency.

Battery

Batteries have a central role in all our everyday objects… as much as in our transportation modes! The development of connected objects (or IoT, Internet of Things) and electrical vehicles (EV) is boosting the technical evolution of the batteries. The challenges of the future are to make them more efficient, more powerful, more compact, and make them last longer. Those needs are driving researchers and manufacturers to explore new materials, including fine oxides.

Batteries have a central role in all our everyday objects… as much as in our transportation modes! The development of connected objects (or IoT, Internet of Things) and electrical vehicles (EV) is boosting the technical evolution of the batteries. The challenges of the future are to make them more efficient, more powerful, more compact, and make them last longer. Those needs are driving researchers and manufacturers to explore new materials, including fine oxides.

Indeed, separators made in polymers show a low thermal integrity of their structure, especially due to a relatively low melting point. After quite a few cycles, internal short circuits and thermal run-away are appearing. The lifetime of the battery is then prejudiced. An alternative approach consists in coating the ceramic on the separator, leading to CCSs (ceramic-coated separators). This method leads to a radical drop of heat shrinkage risks of the polyolefin separator, increasing this way the security and lifetime of the battery.

Discover our battery solutions White Paper

As Baikowski offers a wide range of products to serve the upper part of the value chain, it is obvious that the applications are extremely diversified. The aforesaid applications are only a sample of what can be done!

We keep promoting the co-development of tailor-made products and thus take part in the creation of the sustainable technologies of tomorrow.