Spinel ceramics — known for their optical transmission and high-temperature stability — are widely used in applications ranging from high-energy laser windows to catalytic support water treatment. In the quest for advanced, durable components, researchers continue to face challenges in 3D printing magnesium aluminate spinel with high resolution and minimal defects.

Spinel ceramics — known for their optical transmission and high-temperature stability — are widely used in applications ranging from high-energy laser windows to catalytic support water treatment. In the quest for advanced, durable components, researchers continue to face challenges in 3D printing magnesium aluminate spinel with high resolution and minimal defects.

A study tackled this challenge by testing a stereolithography (SLA) 3D printing method, complemented by a tailored hot isostatic pressing (HIP) process. This study used Baikowski S30CR spinel, a high-purity material with an ultra-fine average particle size of approximately 50 nm and a specific surface area ranging from 25 to 28 m²/g selected for its suitability in formulating printable ceramic pastes for SLA.

Study Purpose: Overcoming Transparency and Resolution Challenges

The primary goal of researchers was to push the boundaries of 3D printed ceramics by achieving transparency and precision that rival conventional fabrication techniques, like die pressing and injection molding, while enabling intricately designed parts.

Furthermore, the study seeks to overcome the challenges posed by organic additives in many 3D printing processes, which often leave behind impurities and defects, thereby compromising the optical performance of the final product.

In summary, key challenges included:

- Achieving Near-Theoretical Transparency: Overcoming the inherent light scattering caused by residual pores and impurities.

- High Printing Resolution: Attaining fine details which are essential for creating intricate optical components.

- Uniform Densification: Ensuring a consistent and dense microstructure free of large pores that can hinder performance.

3D Printing: An innovative Process for Transparent Ceramic manufacturing

SLA 3D printing, a photopolymerization-based additive manufacturing technique, constructs ceramic green bodies layer by layer using a UV laser to cure a photosensitive resin loaded with ceramic powder. After printing, heat treatments remove the resin (debinding), and sintering densifies the ceramic..

SLA 3D printing, a photopolymerization-based additive manufacturing technique, constructs ceramic green bodies layer by layer using a UV laser to cure a photosensitive resin loaded with ceramic powder. After printing, heat treatments remove the resin (debinding), and sintering densifies the ceramic..

Here’s how the process unfolded:

- Preparation of the Printable Paste:

The S30CR powder was meticulously dispersed in a photosensitive acrylate resin using an optimal concentration of dispersants. This created a ceramic paste with a uniform particle distribution and excellent self-holding ability, crucial for high-resolution SLA printing (stereolithography). - SLA 3D Printing:

Using this paste, researchers printed spinel parts on a commercial SLA system, achieving feature resolutions of approximately 100–200 µm — well within the range needed for many optical components. - Multi-Step Debinding and HIP Sintering:

After printing, the green bodies underwent a carefully controlled multi-step debinding process to remove organic additives gradually. This was followed by a two-step sintering process: pre-sintering to boost the green body’s density, and HIP treatment to eliminate residual pores. This sequence was vital to obtaining a dense, almost pore-free microstructure.

Results From the study with S30CR

The printed spinel ceramics achieved a maximum transmittance of ~84.8% at 1550 nm, corresponding to about 97% of the theoretical transmittance limit, marking a notable performance compared to previously reported 3D printed ceramic.

The main results were:

Optical Clarity:

The transparency approached theoretical limits, linked to the uniform, dense microstructure produced by the optimized process.

High Resolution and Design Flexibility:

Printed features as small as ~100–200 µm were achieved — among the finer resolutions for 3D printed transparent ceramics reported in the literature.

Mechanical Properties:

The 3D printed spinel ceramics exhibited a Vickers hardness of ~13.5 GPa, comparable to conventionally processed spine.

Thermal Stability:

Printed spinel maintained transparency and structural integrity when exposed to high temperatures (800–1100 °C.

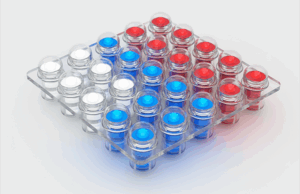

To showcase the potential applications of these 3D-printed spinel ceramics, researchers have fabricated various transparent optical components, including lens arrays, Fresnel lenses, hemispherical domes, and microlattices such as Kelvin cells and simple cubic structures. Notably, the optical imaging performance of some components, like convex lens arrays, was evaluated, demonstrating their capability to produce clear and sharp images without distortion.

To showcase the potential applications of these 3D-printed spinel ceramics, researchers have fabricated various transparent optical components, including lens arrays, Fresnel lenses, hemispherical domes, and microlattices such as Kelvin cells and simple cubic structures. Notably, the optical imaging performance of some components, like convex lens arrays, was evaluated, demonstrating their capability to produce clear and sharp images without distortion.

Furthermore, when utilized as supports for TiO₂ photocatalyst films, these transparent spinel ceramics significantly enhanced photocatalytic reactions compared to their opaque counterparts. This improvement is attributed to their larger illuminated surface area and controlled mass flow through intricately designed channels, highlighting their potential in environmental and energy applications.

The study shows that when SLA 3D printing is combined with carefully optimized powder formulations and controlled post-processing (debinding, sintering, and HIP), transparent spinel ceramics can achieve substantial improvements in both optical quality and geometric precision. This progress highlights how the right alignment of material and process conditions can support innovation in advanced ceramic manufacturing, offering promising directions for future applications and research.

The study shows that when SLA 3D printing is combined with carefully optimized powder formulations and controlled post-processing (debinding, sintering, and HIP), transparent spinel ceramics can achieve substantial improvements in both optical quality and geometric precision. This progress highlights how the right alignment of material and process conditions can support innovation in advanced ceramic manufacturing, offering promising directions for future applications and research.

Read the full study titled 3D Printing of Transparent Spinel Ceramics with Transmittance Approaching the Theoretical Limit

For those seeking a reliable solution to the challenges of 3D printed ceramics, explore our comprehensive 3D printing solutions white paper to discover how Baikowski is leading the way in delivering next-generation materials for tomorrow’s technological challenges.