The quality and performance of our powders are widely recognized in various ceramic applications. A comprehensive PhD thesis titled “Printability of Ceramic Pastes by Robocasting: Application in Solid and Multi-Component Materials” has been completed by Mathilde Maillard in 2022.

The quality and performance of our powders are widely recognized in various ceramic applications. A comprehensive PhD thesis titled “Printability of Ceramic Pastes by Robocasting: Application in Solid and Multi-Component Materials” has been completed by Mathilde Maillard in 2022.

The aim of the project was to develop single- and multi-material ceramic parts (zirconia and alumina) with the least possible consumption of materials and energy. For this reason, additive manufacturing but also microwave heating sintering for consolidation and post-drying were selected.

This research has been instrumental in achieving significant progress in this technique and demonstrating how Baikowski® powders for 3D printing applications contribute to the production of complex geometries and robust ceramic structures.

More information available in our white paper dedicated to

3D printing advanced materials

Robocasting characteristics

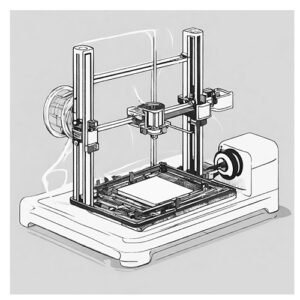

Robocasting, aslo entitled Direct Ink Writing, was chosen over other 3D printing methods because of its potential to produce gradient multi-materials. This technique involves extrusion-based additive manufacturing, allowing for precise layering of ceramic materials that make intricate shapes and customized components possible.

Robocasting, aslo entitled Direct Ink Writing, was chosen over other 3D printing methods because of its potential to produce gradient multi-materials. This technique involves extrusion-based additive manufacturing, allowing for precise layering of ceramic materials that make intricate shapes and customized components possible.

The project aimed at optimizing the composition and processing parameters of ceramic pastes to achieve superior print quality and mechanical properties.

Baikowski® High Purity Alumina and Zirconia Powders

The spray-dried powders were delivered without binder and with a small particle size in order to produce homogeneous inks with suitable rheological characteristics for extrusion.

Baikalox® High Purity Alumina WA15

-

- Specific Surface Area: 23.6 m²/g

- Particle Size Distribution (after deagglomeration):

- D10 = 0.07 µm

- D50 = 0.09 µm

- D90 = 0.12 µm

- Purity: Very low impurity levels, ranging from 0.005% to 0.084%

Baikalox® Zirconia Yttria 3 mol% BSZ3Y

-

-

- Specific Surface Area: 14.1 m²/g

- Particle Size Distribution (after deagglomeration):

- D10 = 0.09 µm

- D50 = 0.15 µm

- D90 = 0.28 µm

-

Advantages of our 4N high purity powders with Robocasting Process

Printability and Rheological Properties: The powders demonstrated excellent dispersion and stability in the ceramic pastes. The rheological properties of these pastes were meticulously adjusted to ensure smooth and continuous extrusion during the robocasting process.

Printability and Rheological Properties: The powders demonstrated excellent dispersion and stability in the ceramic pastes. The rheological properties of these pastes were meticulously adjusted to ensure smooth and continuous extrusion during the robocasting process.

The study showed that by optimizing the solid loading and binder content, the desired viscosity and thixotropy were achieved, enabling compliant shapes of the printed structures.

Structural Integrity and Mechanical Properties: One of the significant achievements of the study was the successful production of dense and mechanically robust ceramic parts. The ceramic structures exhibited high compressive strength and minimal shrinkage upon sintering.

Complex Geometries and Surface Finish: The ability to produce complex geometries with fine details is a critical requirement in additive manufacturing that Baikowski® powders have helped with.

Thanks to the optimized particle size distribution and spherical morphology of the powders, the surface finish of the printed parts was notably smooth, with minimal layer lines.

This characteristic is particularly beneficial for applications requiring precise dimensional tolerances and superior surface quality.

Ceramic 3D Printing Possible Applications With Baikowski® Powders

The ceramic quality achieved in this project with the robocasting method opens new avenues for Baikowski® powders where precision and performance are critical, such as:

Aerospace and Defense: The high strength and thermal stability of ceramic parts produced with our powders can withstand harsh conditions and maintain structural integrity in high-stress environments, including critical structural applications.

Aerospace and Defense: The high strength and thermal stability of ceramic parts produced with our powders can withstand harsh conditions and maintain structural integrity in high-stress environments, including critical structural applications.

Biomedical Devices: The biocompatibility and excellent mechanical properties of the ceramics obtained open new avenues in the biomedical field. Custom implants and scaffolds with complex geometries can be produced. The smooth surface finish and high precision are particularly advantageous for reducing wear and enhancing the longevity of implants.

Electronics and Energy: Our powders enable the manufacture of ceramic parts with precise shapes and dimensions, insulating properties and high thermal stability, critical for electronic devices and energy storage systems.

The study underscores the significant advancements in robocasting 3D printing achievable with Baikowski® powders. The superior printability, structural integrity, and ability to create complex geometries position these powders as a valuable resource in various high-performance applications.

As additive manufacturing continues to evolve, Baikowski® remains at the forefront, driving innovation and expanding the possibilities in ceramic fabrication.

See all the details in the PhD thesis (only in French)