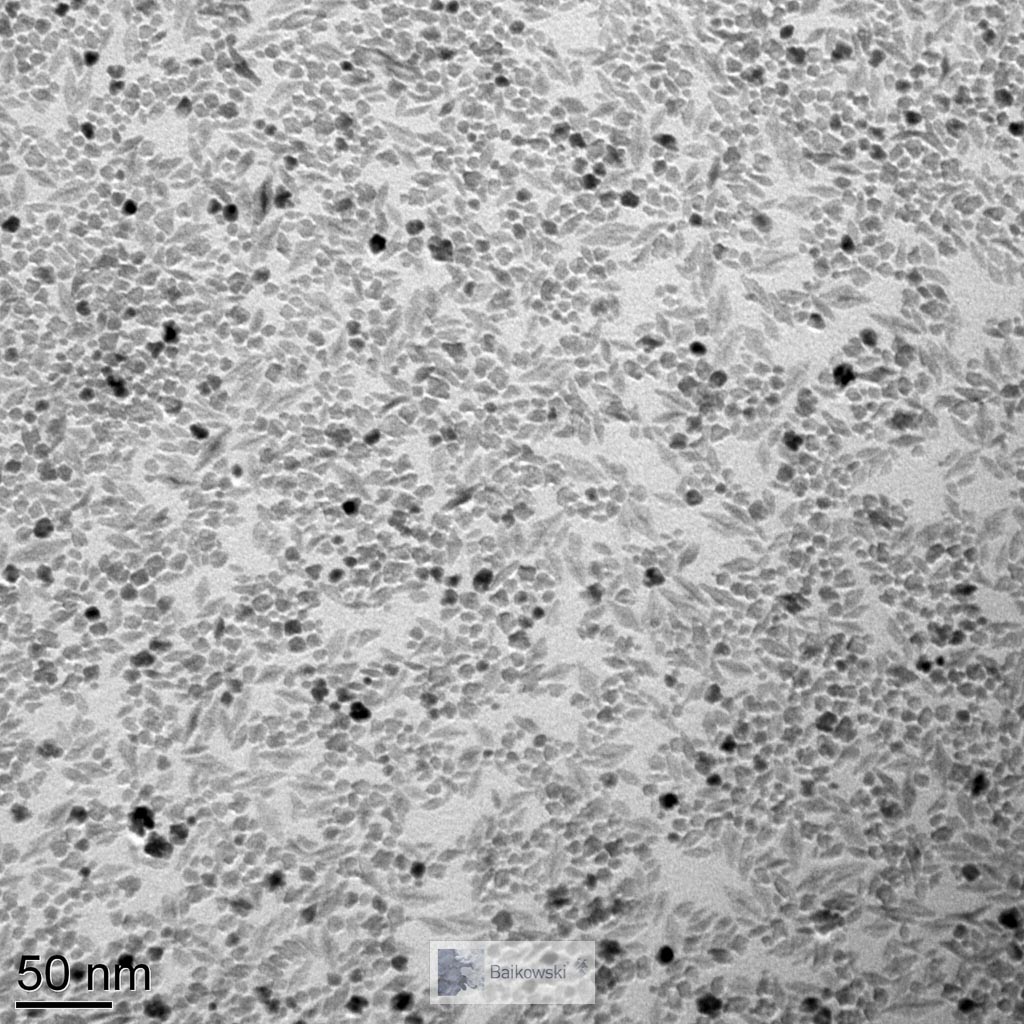

Baikowski is at the forefront of innovation in materials science. Our products enable research and technological advancements. Among the applications, there is the development of graphene oxide (GO) composite membranes anchored on α-alumina substrates as mentioned in the following scientific publication « Composite GO/Ceramic Membranes Prepared via Chemical Attachment: Characterisation and Gas Permeance Properties. »

Baikowski is at the forefront of innovation in materials science. Our products enable research and technological advancements. Among the applications, there is the development of graphene oxide (GO) composite membranes anchored on α-alumina substrates as mentioned in the following scientific publication « Composite GO/Ceramic Membranes Prepared via Chemical Attachment: Characterisation and Gas Permeance Properties. »

By providing a stable and inert platform for GO deposition, the substrates enable the creation of composite membranes with finely tuned pore structures and enhanced separation capabilities in this study, essential for industrial applications.

The porous ceramic substrates made with our High Purity CR6 Baikalox® powder, provide the necessary resistance in high-temperature and corrosive environments where polymeric membranes will fail.

Potential Applications of Composite GO/ceramic membranes

These membranes exhibits enhanced stability and permeance, as well as tailored surface properties that can be employed in various industries to address critical separation and filtration challenges such as :

These membranes exhibits enhanced stability and permeance, as well as tailored surface properties that can be employed in various industries to address critical separation and filtration challenges such as :

- 🌟 Gas Separation: The composite membranes are suitable for applications in industrial gas separation processes, purification of natural gas, and carbon capture technologies thanks to their ability to selectively permeate certain gases while retaining others.

- 🌟 Water Treatment: The hydrophilic and hydrophobic modifications enabled by chemical linkers such as PDA, GPTMS, and APTMS allow the membranes to effectively separate contaminants from water. This application is particularly relevant for wastewater treatment, desalination, and the removal of organic and inorganic pollutants from water sources.

- 🌟 Chemical Processing: The composite membranes’ resistance to chemical products and thermal stability make them suitable for the separation of organic solvents, recovery of valuable chemicals, and purification of reaction products.

- 🌟 Energy Sector: The selective permeation properties can be harnessed to separate hydrogen from other gases, which is a critical step in producing high-purity hydrogen for fuel cells and other energy applications.

- 🌟 Environmental Protection: By enabling the effective separation of harmful gases and pollutants, these membranes can help reduce emissions and treat industrial effluents, supporting cleaner and more sustainable processes.

CR6 Benefits

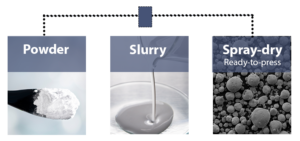

CR6 is a high-purity α-alumina powder of our Baikalox® range of products, well known for its fine particle size and excellent sintering properties.

These characteristics make it an ideal material for creating dense and robust ceramic supports, which are essential for high-performance composite membranes.

The specific properties of CR6 in that application include:

The specific properties of CR6 in that application include:

- 🌟 High Purity: this characteristic ensures minimal contamination, which is crucial for maintaining the integrity of the ceramic substrates and the GO layer deposited on them.

- 🌟 Controlled Particle Size Distribution: It contributes to the creation of uniform macroporous structures. This uniformity is essential for consistent membrane performance, as it influences both gas and water permeance.

- 🌟 Chemical Compatibility: compatibility of CR6 with various chemical linkers, such as polydopamine (PDA), 3-Glycidoxypropyltrimethoxysilane (GPTMS), and 3-Aminopropyltrimethoxysilane (APTMS), facilitated the effective anchoring of GO layers onto the ceramic substrates.

- 🌟 Excellent Sintering Behavior: It allows the creation of mechanically strong and thermally stable supports.

In the referenced study, custom-made α-alumina disks with a ~2 mm thickness and a 22 mm diameter were employed as substrates. The disks were fabricated by pressing the CR6 alumina powder in a custom-made mold and sintering at 800°C for 30 hours and further at 1180°C for 2 hours. One side of the disk was polished until no obvious scratch was observed under visual inspection with a light microscope.

How CR6 Alumina Contributes to Membrane Performance?

One of the primary challenges in composite membrane technology is ensuring strong and stable adhesion of GO layers to ceramic substrates.

The success here is mainly due to :

- 🌟 Enhanced Stability: The CR6-based substrates have showed remarkable stability, maintaining their structural integrity and performance under various conditions.

- 🌟 The smooth and polished surface: these surface characteristics have ensured optimal interaction with the modifying agents (PDA, APTES, GLYMO) and the graphene-based nanocomposites.

- 🌟 Thickness: The substrates have enabled the formation of composite membranes with precise thickness control, optimizing the membrane for different separation applications.

Our high purity CR6 alumina has proven to be a critical component in the advancement of composite membrane technologies. Its superior properties facilitate the creation of reliable and high-performing membrane supports, enabling the successful integration of graphene-based nanocomposites.

This synergy between high-purity alumina and advanced nanomaterials opens new possibilities for applications in gas separation, water purification, and other fields requiring durable and efficient membrane solutions.

Learn more on CR6 composite membrane application in the following study : A Combined Gas and Water Permeances Method for Revealing the Deposition Morphology of GO Grafting on Ceramic Membranes

As noticeable examples:

As noticeable examples: