Our expertise in producing small-sized particles, controlling morphology, optimizing particle size and distribution, and offering various doping options positions us as a partner of choice in advanced material solutions for medical applications.

1- Biomaterials: Zirconia Composite Powders and Slurries

Tailored ZTA Solutions for Bioceramics and Cutting Tools

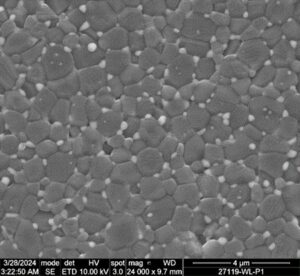

Baikowski®’s ZTA products, which combine tailored alumina and zirconia, exhibits high chemical purity, homogeneous particle distribution, and fine microstructures, to meet the stringent demands of medical applications such as prostheses or implants.

Baikowski®’s ZTA products, which combine tailored alumina and zirconia, exhibits high chemical purity, homogeneous particle distribution, and fine microstructures, to meet the stringent demands of medical applications such as prostheses or implants.

Our customization know how allows us to optimize composition to enhance mechanical properties for medical needs like superior resistance to shocks and wear. It is the case of scalpels and cutting tools inserts that require sharpness and strength to make precise incisions with minimal wear over time.

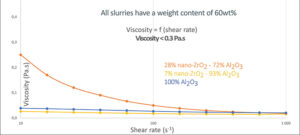

Available in forms such as spray-dried powders and slurries, our ZTA products integrate seamlessly into various manufacturing processes.

Learn more about our ZTA

Moreover, our commitment to quality is underscored by our ISO 22000 certification for food safety, ensuring our products meet stringent European pharmacopeia standards, and ISO 14001 certification for environmental management.

Nanozirconia with High Refractive Index for Dental and Optical Applications

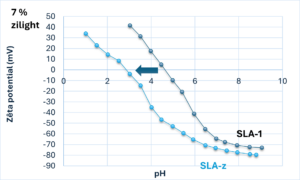

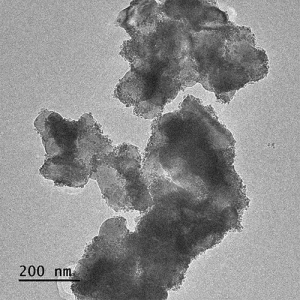

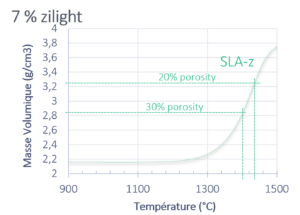

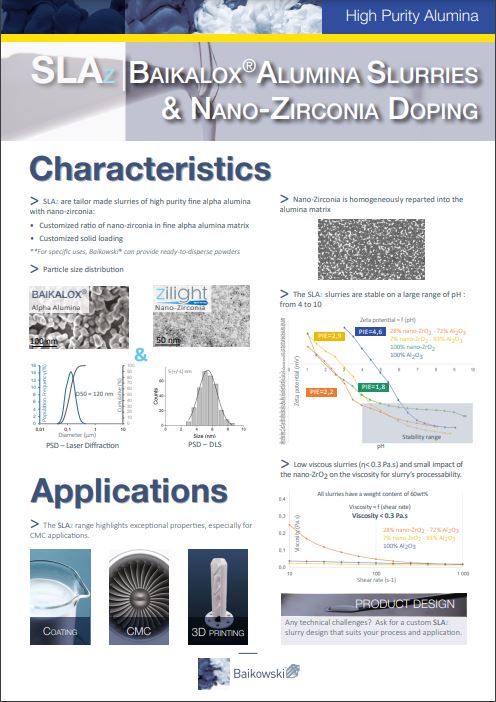

In dental applications, zilight®, with its nano-zirconia particles as small as 5nm, is an ideal choice for dental prosthetics, ensuring durability, aesthetic appeal, and long-term health benefits. Nano-zirconia is biocompatible, brings also radiopacity and thanks to its small size can yield to translucent materials.

In dental applications, zilight®, with its nano-zirconia particles as small as 5nm, is an ideal choice for dental prosthetics, ensuring durability, aesthetic appeal, and long-term health benefits. Nano-zirconia is biocompatible, brings also radiopacity and thanks to its small size can yield to translucent materials.

Additionally, filyxio® YbF3 nanofillers, provides high radiopacity and stronger mechanical properties, but also improved color stability and translucency. filyxio® is the smallest filler on the market, making it ideal for achieving high depths of cure in dental composites.

Learn more about Mathym’s unique dental restorative solutions in our dedicated White Paper Titled:

Nanofiller Dispersions for Superior Dentistry Restorations

In optical applications, zilight® provides customizable refractive index, essential for ophthalmic coatings and displays, without compromising transparency and haze. This results in high-performance optical materials with enhanced scratch and wear resistance.

Download our optical & ophthalmic coatings White Paper

2- Gamma-Alumina for Purification & Dermatological Applications

Baikalox® gamma-alumina powders, such as BA100 and BA105, are used as purification agents during the manufacturing of advanced cosmetic and medical ingredients. They facilitate the removal of metallic and ionic impurities to achieve high-purity compounds suitable for sensitive formulations. For example, this purification process can be applied during the production of hyaluronic acid (HA) used in medical and some high-end cosmetic applications.

In addition, Baikalox high-purity alumina powders, such as CR15, are employed in microdermabrasion procedures and dermatological formulations, where their controlled particle size and morphology enable effective yet gentle exfoliation, suitable for both aesthetic treatments and clinical dermatology.

3- Alumina, ceria and silica for Finishing Polishing

As a leading fine minerals manufacturer, Baikowski® is also committed to finishing polishing of surgical instruments, diagnostic tools, optical components, implants and beyond.

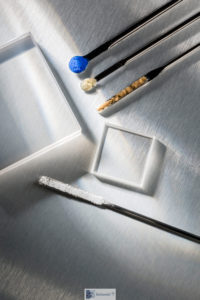

For that purpose, we design custom abrasives powders and slurries such as high-purity alumina, ceria, and silica. Regarding alumina for instance, we can play on the size of the particles and the particle size distribution in order to fit the most closely with the required surface finish, but also tailor the alpha alumina rate into a gamma alumina matrix.

Alumina solutions for Metal Finishing Polishing

High-purity alumina offers exceptional hardness and abrasive qualities necessary for achieving smooth and precise finishes on surgical tools and implants. A polished surface reduces the risk of tissue irritation and promotes better integration with body tissues.

High-purity alumina offers exceptional hardness and abrasive qualities necessary for achieving smooth and precise finishes on surgical tools and implants. A polished surface reduces the risk of tissue irritation and promotes better integration with body tissues.

Baikowski®’s alumina powders and slurries are engineered for optimal particle size and purity, ensuring that the polishing process minimizes surface roughness while maintaining the integrity and sharpness of metal instruments.

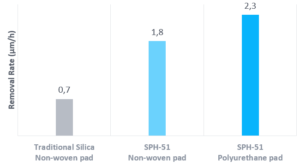

Learn more about how our fine alumina with high specific area outperforms traditional silica solutions, offering both higher performance and greater ease of use in metal polishing and metallograpgy in our dedicated article.

High Puriy Alumina for Optical kiss- Polishing

High-purity alumina is essential for polishing optical components used in diagnostic tools such as endoscopes and microscopes for instance, as well as for lenses, mirrors and prisms.

High-purity alumina is essential for polishing optical components used in diagnostic tools such as endoscopes and microscopes for instance, as well as for lenses, mirrors and prisms.

The exceptional purity of Baikowski®’s alumina ensures that no impurities compromise the optical clarity of these components. As to the controlled particle size distribution of our solutions, a flawless finish that enhance light transmission and image clarity can be achieved.

Explore some of our alumina polishing solutions

Ceria and Silica-Based Polishing Solutions in the medical field

Cerium Oxide (CeO2):

Cerium oxide is commonly used for polishing delicate surfaces like those found in ophthalmic implants or microfluidic devices. Its mild abrasive properties make it suitable too for softer materials, such as certain plastics used in medical devices. For more information on tailored ceria solutions for medical applications, please contact us.

Silica (SiO2):

Silica, particularly in the form of colloidal silica, is a very fine polishing material used for achieving high surface finishes with minimal defect formation. It is ideal for polishing delicate surfaces or materials prone to scratching. However, for a high degree of surface smoothness, especially on harder substrates such as stainless steel, titanium and ceramics, alumina is generally preferred.

To find the ideal abrasive solutions for your substrates, delve into our product selection guide within our Polishing Solutions White Paper and do not hesitate to contact our experts for guidance.

To find the ideal abrasive solutions for your substrates, delve into our product selection guide within our Polishing Solutions White Paper and do not hesitate to contact our experts for guidance.

In fact, Baikowski® Group have a strong expertise based on alumina, silica, ceria abrasive grains and chemical agents, especially when precision and/or selectivity in material removal are demanding.

Download our Polishing Solutions White Paper

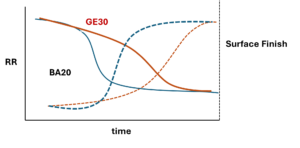

Baikowski® turns formulation know-how—particle crystallinity control, PSD engineering, and chemistries—into repeatable polishing results. With uniform, controlled removal rates, our solutions help you reach the target finish faster, improving performance, reliability, and the overall value of your final products.

Baikowski® turns formulation know-how—particle crystallinity control, PSD engineering, and chemistries—into repeatable polishing results. With uniform, controlled removal rates, our solutions help you reach the target finish faster, improving performance, reliability, and the overall value of your final products.

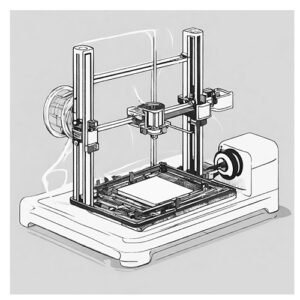

Baikalox® SMA6 (d₅₀ ≈ 0.2 µm) was selected for the work. Its tightly controlled, ultra-fine particle-size distribution supports tuning of gel viscosity, yield stress, and recovery—conditions the study leveraged so the nozzle passes cleanly and the matrix self-heals.

Baikalox® SMA6 (d₅₀ ≈ 0.2 µm) was selected for the work. Its tightly controlled, ultra-fine particle-size distribution supports tuning of gel viscosity, yield stress, and recovery—conditions the study leveraged so the nozzle passes cleanly and the matrix self-heals. Five things have to line up—and SMA6’s PSD/dispersion helps tick each box:

Five things have to line up—and SMA6’s PSD/dispersion helps tick each box: Every Additive Manufacturing line has its own window. Baikowski’s wider portfolio includes specialized alumina grades for diverse processes.

Every Additive Manufacturing line has its own window. Baikowski’s wider portfolio includes specialized alumina grades for diverse processes.

Developing advanced ceramic composites or exploring novel AM approaches? Baikowski offers comprehensive alumina solutions backed by dedicated technical support.

Developing advanced ceramic composites or exploring novel AM approaches? Baikowski offers comprehensive alumina solutions backed by dedicated technical support.

Spinel ceramics — known for their optical transmission and high-temperature stability — are widely used in applications ranging from high-energy laser windows to catalytic support

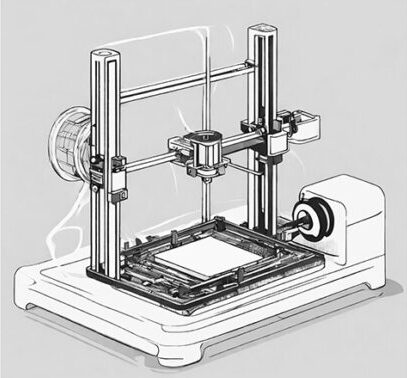

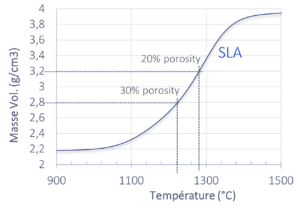

Spinel ceramics — known for their optical transmission and high-temperature stability — are widely used in applications ranging from high-energy laser windows to catalytic support  SLA 3D printing, a photopolymerization-based additive manufacturing technique, constructs ceramic green bodies layer by layer using a UV laser to cure a photosensitive resin loaded with ceramic powder. After printing, heat treatments remove the resin (debinding), and sintering densifies the ceramic..

SLA 3D printing, a photopolymerization-based additive manufacturing technique, constructs ceramic green bodies layer by layer using a UV laser to cure a photosensitive resin loaded with ceramic powder. After printing, heat treatments remove the resin (debinding), and sintering densifies the ceramic.. To showcase the potential applications of these 3D-printed spinel ceramics, researchers have fabricated various transparent optical components, including lens arrays, Fresnel lenses, hemispherical domes, and microlattices such as Kelvin cells and simple cubic structures. Notably, the optical imaging performance of some components, like convex lens arrays, was evaluated, demonstrating their capability to produce clear and sharp images without distortion.

To showcase the potential applications of these 3D-printed spinel ceramics, researchers have fabricated various transparent optical components, including lens arrays, Fresnel lenses, hemispherical domes, and microlattices such as Kelvin cells and simple cubic structures. Notably, the optical imaging performance of some components, like convex lens arrays, was evaluated, demonstrating their capability to produce clear and sharp images without distortion.

Why high-purity sintered spinel matters ?

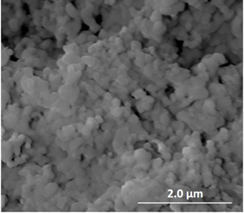

Why high-purity sintered spinel matters ? Baikowski® uses advanced analytical techniques to monitor and maintain these critical parameters, ensuring that every product meets the highest industry standards.

Baikowski® uses advanced analytical techniques to monitor and maintain these critical parameters, ensuring that every product meets the highest industry standards.

One of the most exciting recent developments in spinel technology is the advent of ultra-wide-band-gap spinels, such as zinc gallate (ZnGa₂O₄). These materials are paving the way for next-generation semiconductors, offering superior energy efficiency and thermal stability.

One of the most exciting recent developments in spinel technology is the advent of ultra-wide-band-gap spinels, such as zinc gallate (ZnGa₂O₄). These materials are paving the way for next-generation semiconductors, offering superior energy efficiency and thermal stability.

• Reinforcement: Composites reinforced with Nextel™ 610 fibers and alumina matrices

• Reinforcement: Composites reinforced with Nextel™ 610 fibers and alumina matrices With more than 100 years of expertise and strong R&D capabilities, Baikowski® delivers tailored high-purity oxides for critical applications such as

With more than 100 years of expertise and strong R&D capabilities, Baikowski® delivers tailored high-purity oxides for critical applications such as

With over 120 years of expertise, Baikowski® is a leading provider of advanced materials. We began by offering synthetic sapphire and then later expanded to powder solutions, including polishing solutions for the watchmaking, optics, electronics and semiconductor industries.

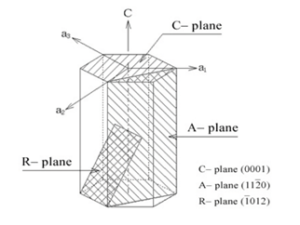

With over 120 years of expertise, Baikowski® is a leading provider of advanced materials. We began by offering synthetic sapphire and then later expanded to powder solutions, including polishing solutions for the watchmaking, optics, electronics and semiconductor industries. The crystal orientation of sapphire is significantly related to polishing difficulty. The C-axis (0001 plane) is the hardest orientation to polish, presenting up to 20% more resistance, and requiring specially formulated slurries to achieve a fine, imperfection-free finish.

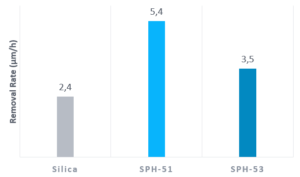

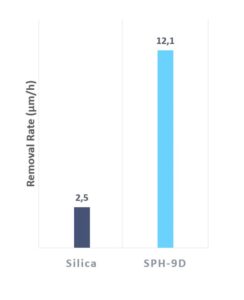

The crystal orientation of sapphire is significantly related to polishing difficulty. The C-axis (0001 plane) is the hardest orientation to polish, presenting up to 20% more resistance, and requiring specially formulated slurries to achieve a fine, imperfection-free finish. Performance of sph-51 Silica solution (A plane)

Performance of sph-51 Silica solution (A plane) Comparison of SPH-51 & SPH-53 Silica solutions (C PLANE 4’’)

Comparison of SPH-51 & SPH-53 Silica solutions (C PLANE 4’’) ALUMINA-BASED SLURRIES COMPARISON

ALUMINA-BASED SLURRIES COMPARISON

This article summarizes the study “Transparent Alumina Ceramics Fabricated by 3D Printing and Vacuum Sintering”, which explored the potential of additive manufacturing to revolutionize ceramic fabrication.

This article summarizes the study “Transparent Alumina Ceramics Fabricated by 3D Printing and Vacuum Sintering”, which explored the potential of additive manufacturing to revolutionize ceramic fabrication.

CMCs are increasingly utilized in

CMCs are increasingly utilized in

Baikowski®’s ZTA products, which combine tailored alumina and zirconia, exhibits high chemical purity, homogeneous particle distribution, and fine microstructures, to meet the stringent demands of medical applications such as prostheses or implants.

Baikowski®’s ZTA products, which combine tailored alumina and zirconia, exhibits high chemical purity, homogeneous particle distribution, and fine microstructures, to meet the stringent demands of medical applications such as prostheses or implants. In dental applications, zilight®, with its nano-zirconia particles as small as 5nm, is an ideal choice for dental prosthetics, ensuring durability, aesthetic appeal, and long-term health benefits. Nano-zirconia is biocompatible, brings also radiopacity and thanks to its small size can yield to translucent materials.

In dental applications, zilight®, with its nano-zirconia particles as small as 5nm, is an ideal choice for dental prosthetics, ensuring durability, aesthetic appeal, and long-term health benefits. Nano-zirconia is biocompatible, brings also radiopacity and thanks to its small size can yield to translucent materials. High-purity alumina offers exceptional hardness and abrasive qualities necessary for achieving smooth and precise finishes on surgical tools and implants. A polished surface reduces the risk of tissue irritation and promotes better integration with body tissues.

High-purity alumina offers exceptional hardness and abrasive qualities necessary for achieving smooth and precise finishes on surgical tools and implants. A polished surface reduces the risk of tissue irritation and promotes better integration with body tissues. High-purity alumina is essential for polishing optical components used in diagnostic tools such as endoscopes and microscopes for instance, as well as for lenses, mirrors and prisms.

High-purity alumina is essential for polishing optical components used in diagnostic tools such as endoscopes and microscopes for instance, as well as for lenses, mirrors and prisms. To find the ideal abrasive solutions for your substrates, delve into our product selection guide within our Polishing Solutions White Paper and do not hesitate to contact our experts for guidance.

To find the ideal abrasive solutions for your substrates, delve into our product selection guide within our Polishing Solutions White Paper and do not hesitate to contact our experts for guidance.

In automotive manufacturing, advanced polishing materials that deliver both precision and an impeccable finish are essential. At Baikowski®, we specialize in producing custom fine alumina powders that not only meet the highest standards but also provide a competitive edge by reducing polishing time and achieving a superior high-gloss finish. This is crucial in the intermediate and superfinish polishing stages, where balancing cutting efficiency with an outstanding gloss and transparency is key.

In automotive manufacturing, advanced polishing materials that deliver both precision and an impeccable finish are essential. At Baikowski®, we specialize in producing custom fine alumina powders that not only meet the highest standards but also provide a competitive edge by reducing polishing time and achieving a superior high-gloss finish. This is crucial in the intermediate and superfinish polishing stages, where balancing cutting efficiency with an outstanding gloss and transparency is key.

As the global demand for effective water treatment systems grows, particularly in regions where access to clean drinking water is scarce, the development of

As the global demand for effective water treatment systems grows, particularly in regions where access to clean drinking water is scarce, the development of In conclusion, spinel-based composite membranes offer a solution for filtering viruses and other microorganisms from drinking water, with the added benefit of being durable and regenerable. The Baikowski®’s high-purity spinel powder, S25CR, play a role in these advanced filtration technologies, ensuring both high filtration efficiency and long-term stability.

In conclusion, spinel-based composite membranes offer a solution for filtering viruses and other microorganisms from drinking water, with the added benefit of being durable and regenerable. The Baikowski®’s high-purity spinel powder, S25CR, play a role in these advanced filtration technologies, ensuring both high filtration efficiency and long-term stability.

ts are looking for

ts are looking for  The control of Mathym’s zirconia grain size to less than 100 nm enables to produce high translucency ceramics without compromising solidity. Moreover, the adjustment of yttria doping in the 8 mol.% range also allows enhanced optical transparency. The obtained ceramics exhibit opalescence similar to natural enamel, creating a bluish and orange appearance under different lighting conditions.

The control of Mathym’s zirconia grain size to less than 100 nm enables to produce high translucency ceramics without compromising solidity. Moreover, the adjustment of yttria doping in the 8 mol.% range also allows enhanced optical transparency. The obtained ceramics exhibit opalescence similar to natural enamel, creating a bluish and orange appearance under different lighting conditions. Mathym’s commitment to innovation extends beyond zilight® nano-zirconia suspension.

Mathym’s commitment to innovation extends beyond zilight® nano-zirconia suspension.

This article summarises key results from the scientific publication “ «

This article summarises key results from the scientific publication “ «  These membranes exhibits enhanced stability and permeance, as well as tailored surface properties that could be employed in various industries to address critical separation and filtration challenges such as :

These membranes exhibits enhanced stability and permeance, as well as tailored surface properties that could be employed in various industries to address critical separation and filtration challenges such as :

Aerospace and Defense: The high strength and thermal stability of ceramic parts produced with our powders can withstand harsh conditions and maintain structural integrity in high-stress environments, including critical structural applications.

Aerospace and Defense: The high strength and thermal stability of ceramic parts produced with our powders can withstand harsh conditions and maintain structural integrity in high-stress environments, including critical structural applications.

As the aviation industry continues to shape the future and work towards decarbonization,

As the aviation industry continues to shape the future and work towards decarbonization, Developing high quality Ox/Ox CMCs with superior performance properties for critical components required precise control over the characteristics of high purity alumina-based powders and slurries such as :

Developing high quality Ox/Ox CMCs with superior performance properties for critical components required precise control over the characteristics of high purity alumina-based powders and slurries such as : Mechanical strength

Mechanical strength