Supporting Biodiversity Through Beekeeping

Nestled within a vast parkland in Poisy (Haute-Savoie, France)—and just 50 m from the forest—our site is far more than a production facility; it’s a living ecosystem. In April 2025, we strengthened this connection to nature by welcoming four beehives to our grounds, in partnership with Un Rêve d’Abeilles.

These industrious pollinators play a vital role in supporting biodiversity, and we couldn’t help but be inspired by their remarkable organization and tireless dedication.

This initiative marks the beginning of a beautiful collaboration and perfectly complements Baikowski’s broader CSR commitments. From long-term environmental stewardship and reducing water & gas consumption, to emissions control and industrial-waste recycling, these hives are a natural extension of our responsible practices.

The installation of these four beehives is a new milestone in this journey—and we’re already looking forward to the sweet rewards of this collaboration.

📸 Take a look below at their installation and their new home

🐝 FAQ – About Our Bees

Q: Why set up hives on our site?

A: Bees are vital pollinators, supporting plant diversity and ecosystem health—key elements of our biodiversity and CSR mission .

Q: When will we see honey?

A: The bees were installed in April. Assuming healthy growth, we expect our first honey harvest in Jully—a sweet milestone!

Q: How likely is it to get stung?

A: Very unlikely. The species we’re using is known for its docile nature, and our honey bees will not sting unless disturbed or threatened.

Q: Will the bees affect local wildlife or wild bees?

A: When habitat is abundant and healthy, honey bees coexist well with wild bee populations. Our parkland offers plenty of flowers and natural forage .

France 2030 aims to lead the country in decarbonization by achieving carbon neutrality by 2050, and plans to allocate 30 billion euros to support initiatives that accelerate the ecological transition.

France 2030 aims to lead the country in decarbonization by achieving carbon neutrality by 2050, and plans to allocate 30 billion euros to support initiatives that accelerate the ecological transition.

Established in 1904 by the Baikowski family with the ambitious goal of producing synthetic sapphire using the Verneuil method,

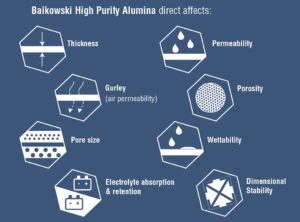

Established in 1904 by the Baikowski family with the ambitious goal of producing synthetic sapphire using the Verneuil method,  With a strong commitment to innovation, Baikowski®’s mission is to provide High Purity Alumina Powders & formulations, Spinel, Phosphor, Zirconia, Ceria and other specialty oxides for cutting-edge applications such as:

With a strong commitment to innovation, Baikowski®’s mission is to provide High Purity Alumina Powders & formulations, Spinel, Phosphor, Zirconia, Ceria and other specialty oxides for cutting-edge applications such as: Baikowski®’s commitment extends beyond industrial excellence to

Baikowski®’s commitment extends beyond industrial excellence to

Mathym®, Lyon, FR

Mathym®, Lyon, FR